Description

Die casting is a metal casting process that is characterized by forcing

molten metal under high pressure into a mold cavity. The mold cavity is created

using two hardened tool steel dies and work similarly to an injection mold

during the process. The typical material for high pressure die casting are

aluminum, zinc, magnesium, copper, and tin-based alloys. Depending on the type

of metal being cast, a hot, or cold-chamber machine is used. Auwell typically

provides services for hot chamber aluminum and zinc die casting molds and

products.

Presio handiko trokelaketa galdaketa barrunbe bakar edo anitzetan egin daiteke, unitateen trokelen erabilera edo trokelen konbinazioa produktuaren eskakizunen araberakoa da.

Different type of dies in the die casting process:

-Single cavity to produce one component

-Multiple cavities to produce several identical parts

-Unitatea hiltzen da zati desberdinak aldi berean sortzeko

-Konbinazio trokel bat muntatzeko hainbat zati desberdin ekoizteko

The casting equipment and the metal dies represent large capital costs. It

is thus especially suited for a large quantity of small to medium sized

castings, which is why high pressure die casting produces more castings than

any other casting process. High pressure die casting is characterized by an excellent

surface finish (by casting standards) and dimensional accuracy.

High pressure die casting is now considered as an industrial procedure,

used to manufacture parts for sale, or as part of machines for any other

commercial or industrial production. The process allows production of accurate

products to the desired size, shape, and thickness with tight tolerances,

making it the most simple yet effective casting process, essential for creating

metal parts with specified details and quality demands.

High pressure die casting is proven as beneficial to products. In this

process, various modifications can be made to the production. Manufacturers

spend less funds and less time in the making of the produced die-cast parts

which are more attractive to the eyes of the buyers.

Presio altuko galdaketa bidez, mekanizazio osteko eta errepikatutako moldeak ezabatu daitezke. Prozesua oso ekonomikoa da eta prozesu honekin egindako produktu amaituak zehatzak eta iraupen luzekoak dira.

Presio handiko galdaketa prozesua beste edozein fabrikazio-teknika baino forma eta osagai ugari eskaintzen duen prozesu eraginkorra eta ekonomikoa da.

Honako hauek dira presio altuko galdaketaren abantailak:

-High-Speed Production

Presio altuko trokelatuak molde konplexuak onartzen ditu tolerantzia estuagoen barruan beste masa ekoizpen prozesu askorekin alderatuta. Mekanizazio gutxi edo bat ere ez da beharrezkoa eta milaka galdaketa identiko egin daitezke tresneria osagarriak egin aurretik.

-Zehaztasun eta egonkortasun dimentsional bikaina

High pressure die casting

produces parts that are durable with dimensional consistancy while maintaining

close tolerances. They are also heat resistant.

-Strength and weight

High-pressure die casting

parts have considerable high tensile strength at 415mpa. Thin wall castings are

stronger and lighter than those possible with other casting

methods.

-Akabera teknika anitzak

High-pressure die-cast

parts can be produced with smooth or textured surfaces, and they are easily

plated or finished with minimum surface preparation.

-Muntaketa sinplifikatua

Presio altuko die casting bidez lotzeko elementu integralak eskaintzen ditu, hala nola zulak eta zutoinak. Zuloak neurtu eta neurrira egin daitezke, kanpoko hariak bestela igarotzen dira.

Auwell offers various types of services to fulfill the clients’

requirements. We have a rich experience in designing and manufacturing high

pressure die casting tools for the worldwide market, especially EU countries. We

produce dies and cast products, including machining and surface treatment, for

our clients.

Technical Specifications

-Core Elementua Materiala

H13, 1.2344 (X40

CRMoV51), 1.2367(X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Bolster Material:P20,

1.2312, 1.2738

-Standard Components

HASCO, LKM standard or custom

made

-Popular Product Material

AL226, AL230, AlSi10Mg, 360.380.383, 413 eta A304 K aleazioak, ADC12, ADC10, Zamak 3, Zamak 5, ZA-8, ZA-12eta ZA-27 etab.

-Product surface finishing

Includes but is not

limited to: brush, line polishing, high gross polishing, mirror polishing, sand

blaster, anodizing, zinc-plating, chrome-plating, nickel-plating, powder

coating, silver coating, E-coat, wet paint, silk screening and stenciling etc.

-Maximum Machining Closing

Force

4,000 tons, part weight:

5-30,000g

Abantailak

-Rich Experience

More than 20 years of

experience in high pressure die casting products development and production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Orokorrean, akutazioa eskaintzen dugu 3 laneguneko epean. Fabrikazioko azken teknologiak eta instalazioak konbinatuz, Auwellek hasierako laginak eman ditzake 5 astetan proiektu sinpleetarako.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for high pressure die casting projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-QC politika zurrunak

Kalitate politika zorrotzena materialen kontroletik abiatzen da, eta azken bidalketa aurreko ikuskapenera arte jarraitzen da. Materialen ziurtagirien artean, errotaren ziurtagiria, hirugarrenen osagai kimikoak eta jabetza mekanikoen txostenak daude, baita RoHS eta REACH txostenak ere hala eskatuta. Beste txosten batzuk dimentsioen txostenak, gainazalaren tratamenduaren lodiera eta gatz-lainoaren proben txostenak daude, etab. Gure prozesuak egituratzen ditugu, fluxu-diagramak eta kontrol-planak sortu aurretik, ziurtatu QC prozesu guztiak ISO9001-2015 eskakizunen eta zehaztapenen marrazkiaren arabera.

-Ordainketa Malguaren Epe

Masa ekoizteko, ordainketa baldintza malguak eskaintzen ditugu, arrazoizko kreditu baldintzak emango dira, bezeroak bakarrik ordaindu du jasotako produktuarekin pozik dagoenean. Epe luzerako proiektuetarako, deialdien inbentario zerbitzuak eskaintzen ditugu entrega azkarreko eskakizunetarako.

Applications

Presio altuko galdaketa-produktuak asko erabili dira ia industria sektore guztietan, besteak beste:

-Aerospace and defense

-Automobilgintza

-Agriculture Machinery

-Energy

-Elektronika

-Eraikuntza

-Transportation

-Industriala

-Consumer Products

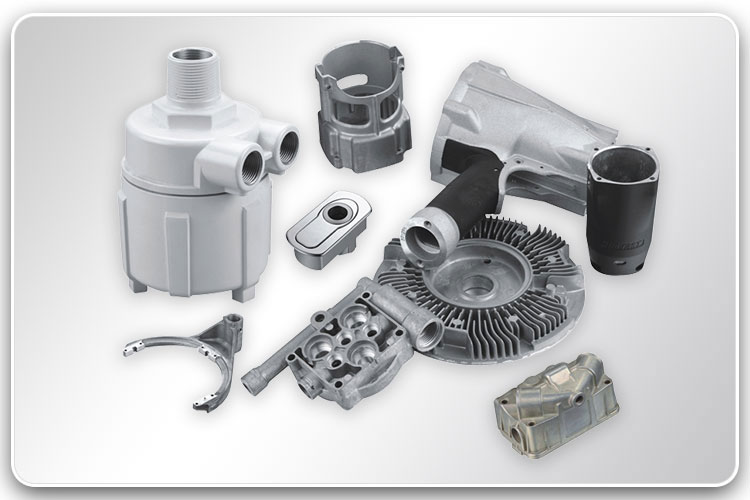

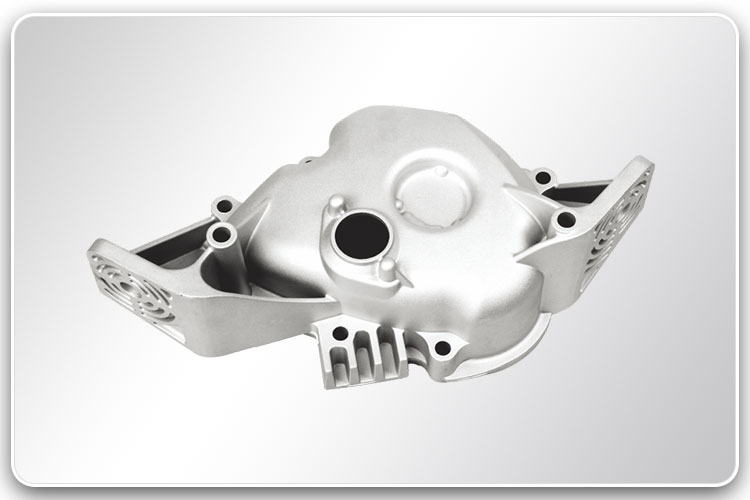

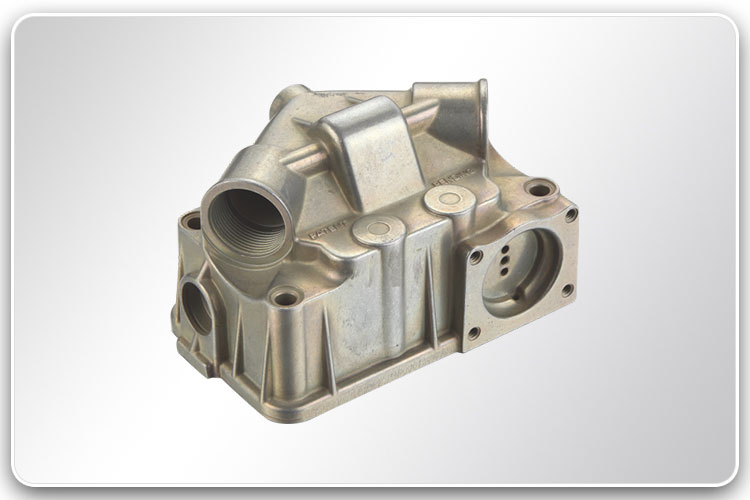

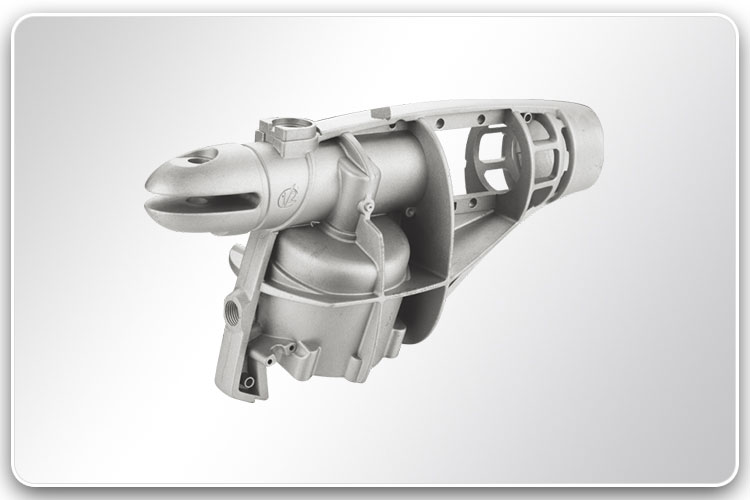

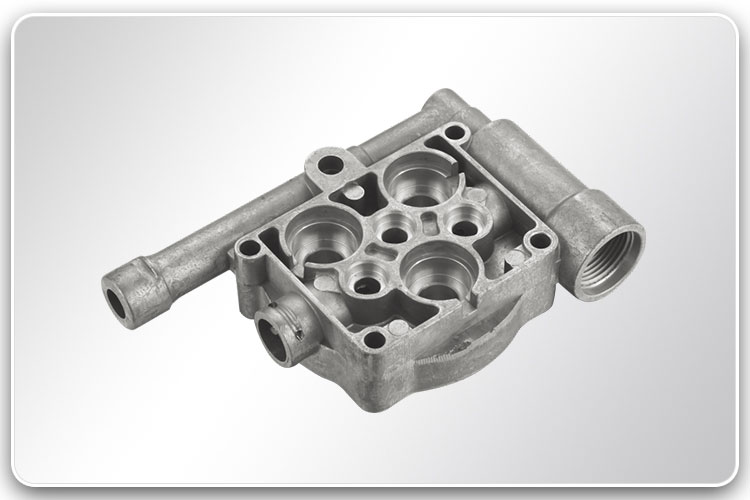

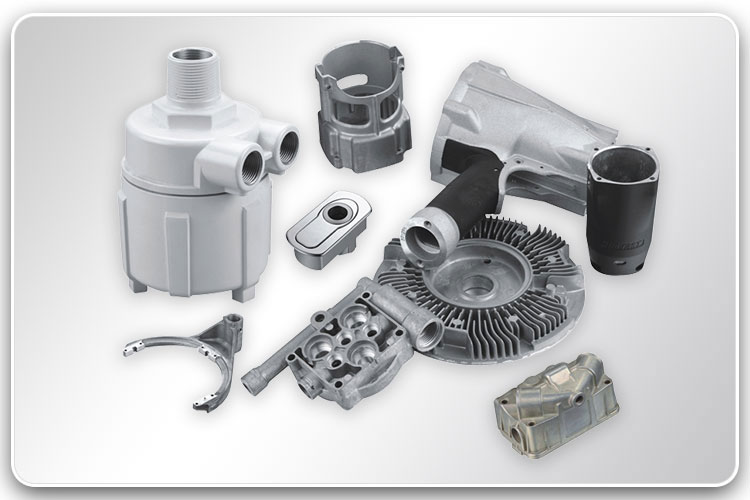

The following

catalogues of high pressure die casting products are the ones which Auwell has

produced and supplied to our distinguished worldwide clients. Please click the

relevant pictures for details. Please be advised, most of the products are for demonstration

purpose only.

Aluminum Die Casting Automobilgintza Parts

Aluminum Die Casting Automobilgintza Parts

Aluminum Die Casting Industriala Parts

Aluminum Die Casting Industriala Parts

High Pressure Die Casting Tooling

High Pressure Die Casting Tooling

Presio altuko zinkezko galdaketa piezak

Presio altuko zinkezko galdaketa piezak

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик