Description

Rubber & Silikona molding is a manufacturing process whereby an amount

of uncured rubber or silicone is transformed into a usable product.

Kautxua eta silikona moldeatzeko 3 mota daude:

-Rubber compression molding

Aurrez zehaztutako gomazko konposatu kopuru bat zuzenean moldearen barrunbean jarrita eta gero barrunbearen forman konprimituz, moldearen bi aldeak itxiz.

-Rubber injection molding

In this Rubber &

Silikona molding process the uncured rubber compound is heated to a liquid

state before being injected into a mold. The product is released by opening the

mold and closing it again to receive the next injection.

-Gomazko transferentzia moldura

Gomazko eta silikonazko moldaketa prozesu honetan zehar sendatu gabeko kautxua edo siliziozko konposatuak âpoteaâ izeneko moldeaz aparte jartzen dira irekidura batetik zehar nahi den produktuaren forman zorrotzera behartu aurretik. Sendatzean, moldea zatitu egiten da azken produktua askatuz.

Auwell-en materiala Kautxua eta silikona moldeatzeko:

-Nitrile or Buna-N

The most popular and

low-cost solution in Rubber & Silikona molding

-Nitrilo hidrogenatua

This is a more expensive

hydrogenated variation of Nitrile polymer, which increases its resistance to

heat, petroleum products, and ozone almost fivefold.

-Etilenopropileno Dienomonomeroa (EPDM)

Commonly used in rubber

molded products for steam systems, vehicles panel seals, and braking systems

due to its high resistance to brake fluid

-Silikona

Tenperatura altu eta baxuen eraginpean egotea, oso malgua da eta eguraldi erresistentzia ona du.

-Fluorosilizona

Combines the temperature

range advantages of silicone with the resistance to oil, fuel, and solvents

found in fluorocarbons.

-Neoprenoa

As a strong multi-purpose

material, it can be used in a large number of rubber molding solutions. It has

good fire resistant and abrasion properties and is frequently used in the

manufacture of mass transit and transportation equipment

-Natural Rubber

A natural product

produced from latex derived from the rubber tree

-SBR (Estireno butadienoa)

Kautxua moldatzeko erabil daitekeen polimero eraginkorrena eta maiz erabiltzen da pneumatikoak, diafragmak, zigiluak eta junturak ekoizteko eta gomazko beste pieza batzuk ekoizteko.

-Fluorocarbon

This relatively expensive

rubber compound combines a wide range of chemical resistance and

high-temperature properties.

-Butyl

Gasa iragazkortasunarekiko erresistentzia handia du. Horrek konponbide ezin hobea bihurtzen du presio altuko gas eta hutseko sistemetarako zigiluak ekoizteko

-Urethane

A fairly high priced, but

commonly used material in applications subject to high pressure and constant

shock loads

Advantages

-Rich Experience

More than 20 years of

experience in Rubber & Silikona molding parts development and part

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Aldaketa azkarra

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to provide fast prototypes in 5

working days, for simple and small size tooling, we are able to deliver first

sample in 2 weeks.

-Irtenbide hornitzaile integrala

Auwell provides

comprehensive services for Rubber & Silikona molding parts development

starting from designing, through prototyping, tooling/fixture development,

sampling, mass production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Rubber & Silikona molding parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Ordainketa Malguaren Epe

For tooling, the general

payment term is 50%-50%, meant 50% deposit, 50% after first sample free. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Lotutako produktuak

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Plastiko injekzioaren gainmoldaketa

Plastiko injekzioaren gainmoldaketa

Plastikozko Termoformaketa Piezak

Plastikozko Termoformaketa Piezak

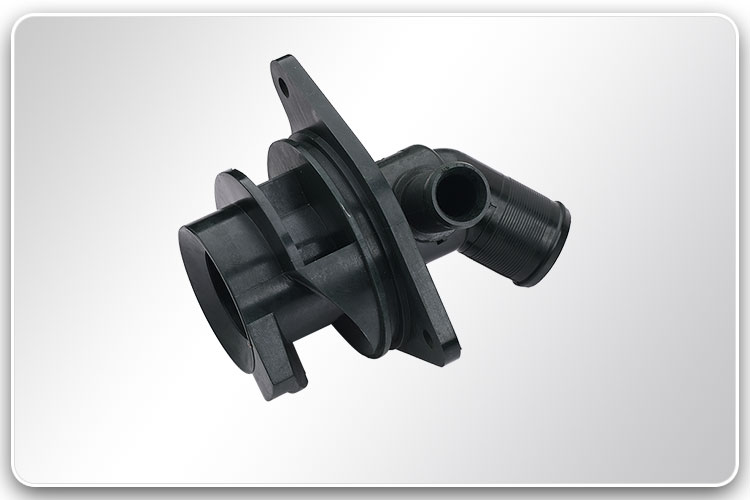

The following catalogues of Rubber & Silikona molding parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик