Deskribapena

Injekzio bidezko moldaketa damanufacturingpiezak ekoizteko prozesua urtutako materiala injektatuzmoldea. Plastic Injection Molding is one of the most frequently used manufacturing

processes for creating plastic parts. Thanks to its high-precision,

repeatability, and cost efficiency at scale, plastic injection molding is used for

a variety of products and parts from the smallest insert up to large automotive

& aerospace parts.

The plastic injection molding process requires an injection molding

machine, raw plastic material, and a machined mold. The raw plastic material is

first melted in the injection unit and is then injected into the mold, where it

cools and solidifies into the final plastic part.

The key steps in the injection molding process include:

-Clamping

The two sides

of the mold are closed and clamped shut.

-Injection

The material is fed into

the machine and pushed towards the mold. While this is happening, the material

is melted by heat and pressure. The plastic is then injected into the mold,

this process is called “Shot”.

-Hoztea

The plastic in

the mold cools and solidifies into the shape of the part.

-Kanporatzea

After the part

cools, it is ejected from the mold.

Auwellek 2 negozio eredu eskaintzen ditu bezeroaren beharrak asetzeko plastikozko injekzio proiektuetarako. Hain zuzen, tresneria modeloak edo azken produktuen modeloak soilik hornitu.

-Tresneria ereduak soilik

Negozio eredu honetarako, Auwellek produktuaren diseinuan eta makinaren datuetan oinarritutako tresneriaren diseinua eskaintzen du bezeroaren baieztapenerako, xehetasunen artean tresneriaren egitura, bizitza, tresneria materiala, gogortasuna, etab. Tresneria aukera honetarako, pieza estandarretarako, mundu osoan ezagunak diren ohikoenak erabiliko ditugu mantentze lanetarako. Oro har, aukera hau tamaina handiko eta bolumen handiko produktuetan hobesten da, PlasticInjection Tooling Automobilgintza negozio eredu honen katalogo tipikoa da.

-Final Products Models

Negozio eredu honetarako, Auwell plastikoa injektatzeko piezak moldatzeaz arduratzen da eta bezeroaren zehaztapenak betetzen ditu. Injekzio makina mota eta erabilitako tresnen egitura / diseinua gure taldeak erabakitzen du. Negozio eredu honetarako, bezeroak tresneriaren kostua ordaintzen duenean, Auwell arduratuko da tresneriaren mantentze-lanez eta produktuaren bizitza osorako ordezkapenaz. Eredu hau tamaina txikian eta plastikozko injekzio zehatzak moldatzeko piezetan hobesten da. Mesedez, kontsultatu â € œPlastic Injection Parts” section for more details.

Bi negozio-ereduaren beste desberdintasun funtsezkoa da: "Tresneria soilikModelarentzat", moldearen kostua "Azken Produktuen Eredua" baino handiagoa da "Azken Produktuen Eredua" ren kasuan, Auwellek ez du tresna-garapenaren marjina. "Azken Produktuen Eredua" ren kasuan, bezeroek moldea hartu nahi badute, beste hornitzaile batengana aldatu, ez dago bermatuta moldeak beste fabrikazio bateko beste makina batean ondo funtzionatzen duenik, eta moldearen garapen kostuaren proportzio jakin bat kobratuko da. moldea transferitu aurretik.

Apart from plastic injection molding, we also provide the following

services:

-Rapid 3D printed prototypes

-Overmolding

-Txertatu moldura

-Termoformaketa

-Rubber & Silicone

Molding

Technical Specifications

-Materiala

Plastikozko injekzio bidezko moldaketa zerbitzuetarako eskuragarri dagoen material plastikoa:

Ø PA 6/6 | Polyamide 6/6, Nylon 6/6

Ø PARA | Poliaril Amida

Ø PBT | Polybutylene Terephthalate, Valox

Ø PBT-PET | Polibutileno Tereftalato-Polietileno Tereftalato

Ø PC | Polikarbonatoa

Ø PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

Ø PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

Ø PC-PET | Polycarbonate-Polyethylene Terephthalate

Ø PCT | Poliziklohexilendimetilenotereftalatoa

Ø PE | Polyethylene

Ø PE-PP | Polietilenoa-Polipropilenoa

Ø PE-PS | Polietileno-Poliestireno

Ø PEBA | Polyether Block Amide

Ø PEEK | Polieter eter zetona

Ø PEI | Polieterimida, Ultem

Ø PES | Polyether Sulfone

Ø PET | Polietilenotereftalatoa, rinita

Ø PLA | Azido Polilaktikoa

Ø PMMA | Polymethyl Methacrylate, Acrylic

Ø POM | Polimetimetileno azetala, Delrin

Ø PP | Polypropylene

Ø PPA | Poliftalamida

Ø PPS | Polifenilen sulfuroa, Ryton

Ø PS | Poliestireno

Ø PS-PPE | Polystyrene-Polyphenyl Ethers, Noryl

Ø PSU | Polisulfona, Udel

Ø PVC | Polyvinyl Chloride (Shore D)

Ø PVDF | Polyvinylidene Fluoride

Ø SAN | Styrene Acrylonitrile

Ø TPO | Poliolefina termoplastikoa

Ø TPU | Poliuretano termoplastikoa (Shore D)

Ø Custom-sourced Resin

-Moldbase

LKM, HASCO, 1.1730, S50C, S55C, 1050, 1055

-Active Elements

Ø P20, 1.2311, 1.2312, 1.2738, 1.2343, 1.2344, H11, H13, 420

Ø ASSAB: 718, 718S, 718H, S316 / S316H / S316 SUP / S316H SUP, POLMAX / 168

Ø SAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

Ø DAIDO: NAK80, NAK55, PX88, PX4, PX5, S-Star (A)

Ø BOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Mould Surface

Argazki akuafortea, higadura, egituraketa, lehergailua, lerro leuntzea, leundutako gordin leuntzea, ispilua leuntzea.

-Makinak: 100-3.000 tonako ixteko indarra

Abantailak

-Rich Experience

20 urte baino gehiago daramatza plastikozko injekzio bidezko tresnen garapenean eta piezen ekoizpenean, batez ere Europako eta Ipar Amerikako merkatuetan, mundu osoko material, teknika eta kalitate estandarrak ondo ulertuz.

-Aldaketa azkarra

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to provide fast prototypes in 3

working days, for simple and small size tooling, we are able to deliver first

sample in 4 weeks.

-Irtenbide hornitzaile integrala

Auwellek zerbitzu integrala eskaintzen du plastiko bidezko injekzioa moldatzeko proiektuetarako, diseinutik hasita, prototipoak, tresneria / lanabesen garapena, laginketa, produkzio masiboa eta salmenta osteko laguntza logistikoa eta logistikoa.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Materiala certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Ordainketa Malguaren Epe

For tooling, the general

payment term is 50%-40%-10%, meant 50% deposit, 40% after first sample free and

10% 2 weeks after client receive tooling or first batch product delivery. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Applications

-Plastikoa injektatzeko produktuak asko erabili dira ia industria sektore guztietan, besteak beste:

-Aerospace and defense

-Automobilgintza

-Agriculture Machinery

-Energy

-Electronics

-Construction

-Transportation

-Industrial

-Kontsumorako produktuak

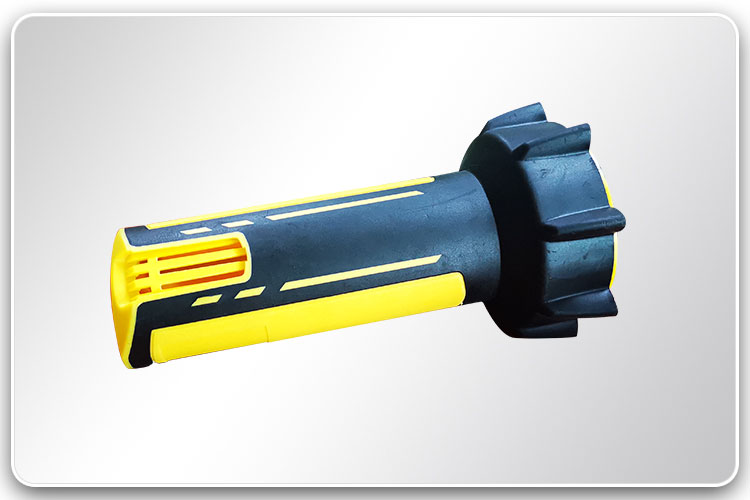

Plastiko bidezko injekzio bidezko produktuen katalogo hauek Auwellek mundu osoko gure bezero ospetsuei ekoiztu eta hornitu dizkie. Egin klik dagokion irudian xehetasunak lortzeko. Mesedez, beadvised, produktu gehienak erakusteko helburuarekin soilik daude.

Plastic Injection Mold for Automobilgintza Parts

Plastic Injection Mold for Automobilgintza Parts

Plastic Injection Parts

Plastic Injection Parts

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastic Termoformaketa Parts

Plastic Termoformaketa Parts

Kautxua eta silikonazko moldura

Kautxua eta silikonazko moldura

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик